|

|

Diggin In by Kurt Riesselmann

It’s dark, it’s wet and—most of all—it’s huge.

Miners of the S.A. Healy company are carrying out the final excavation work

for a new underground facility at Fermilab that could easily store thousands

of cars, neatly lined up and stacked on top of each other. Since April 2000,

construction crews have worked in three shifts, six days a week, to create

an intricate system of tunnels and halls.

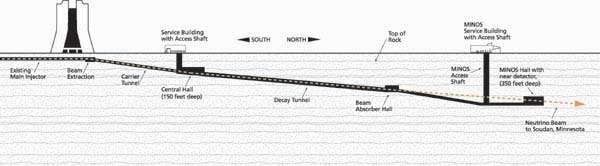

But this new space isn’t tagged as a parking garage. Physicists will use

the new caverns to build a research laboratory called Neutrinos at the Main

Injector (NuMI). Two large underground halls and 4,000 feet of tunnels will

host scientific equipment to create and analyze neutrinos, the most evasive

particles of the universe.

Scientists will crash protons from Fermilab’s Main Injector accelerator into

a graphite target in the first NuMI underground hall, at a depth of 150 feet.

The resulting neutrinos will then traverse a second underground hall, 350 feet

deep, where a particle detector will record the neutrinos’ properties. From

there the neutrinos will continue their journey through 450 miles of rock

to hit a second detector in a former iron mine in Soudan, Minnesota. While

traveling through the rock—no tunnel is needed—the neutrinos may “change

flavors,” transforming from one type into another. Because of its relevance to

the evolution of the universe, this process is of great interest to physicists.

But unlike conventional transportation tunnels, NuMI’s will never have traffic

jams.

“The NuMI underground construction is different from—and probably a bit

more difficult than—a transportation-tunnel project,” said John Sollo, NuMI

construction coordinator. “Access to the NuMI main tunnels is only through

vertical shafts rather than a drive-in portal from either end.”

In the absence of elevators (to be installed this fall), workers enter the

construction site via a metal cage that is lifted and lowered into the tunnels

by a crane. Every piece of equipment, from shovels to front-end loaders,

has come through the access shafts. And every piece of rock has gone out

through one of the shafts. Millions of pieces. Or more precisely: one hundred

thousand cubic yards of rock, more than 2,000 truckloads.

Excavating tunnels is nothing for the faint at heart. The environment

underground is cold and wet. Temperatures of 55 degrees Fahrenheit are the

norm, and fog is not unusual. During the construction, a couple of hundred

gallons of water have entered the NuMI tunnels—per minute! Even after the

facility is complete, engineers expect a continued inflow of approximately

150 gallons per minute, which will be removed by powerful sump pumps.

Taking no risk

“The only way to improve safety culture is through

communication,” said Mike Andrews, who joined

the NuMI project after the accident to become the

coordinator for environment, safety and health. “We

really beefed up the daily hazard analysis program.

We have safety meetings, toolbox meetings and

daily planning meetings to help the crew members

understand what the issues are. The foremen are

now very clear on what they mean and how they

present it. And the miners know that we don’t just

talk about safety, but that we really mean it.”

“Safety constantly needs attention,” said

construction manager Dixon Bogert. “It’s fair to

say that safety has improved, but it’s not an area

in which we can relax.”

Having a blast

“The various NuMI tunnels and halls have different

dimensions and cross sections,” said project

engineer Chris Laughton. “Healy chose the

excavation methods that they considered the

best for the different parts of the project. Using

a variety of excavation techniques is not a

technical challenge but a logistical one.”

Miners used the tunnel boring machine to excavate

the 21-foot-diameter tunnel between the two

underground halls. At its best, the TBM advanced

by more than 70 feet a day, but more typically

mined at less than half that rate. To excavate the

access shafts and underground halls, miners

carried out more than 400 blasts, removing

up to ten feet of rock in one blast.

To limit the impact of blasts on both Fermilab’s

scientific facilities and the surrounding

neighborhood, miners had to follow strict

specifications.

“The noise and vibration restrictions [specified in

the contract with S.A. Healy] were a main issue

during drill and blasting,” explained Sollo. “Those

restrictions are common in urban areas, but

unusual for most underground work.”

Fermilab closely monitored the noise and vibration

created by each blast. Although the blasts never

exceeded vibration levels, some blasts were much

louder than expected. Unfavorable northeast winds

and dense cloud coverage sometimes intensified

and projected the noise into the adjacent

neighborhood, startling neighbors by rattling

windows.

“We’ve greatly appreciated the patience and

cooperation of our neighbors,” said NuMI project

manager Greg Bock. “Their observations and

feedback were as valuable to us as the data we

obtained from scientific monitoring equipment.”

The NuMI excavation, with only a few blasts still

to come, has lasted twenty-six months, so far

some six months longer than originally anticipated.

According to a revised schedule, accepted by

a Department of Energy review committee in

September 2001 (see FERMINEWS, Sept. 28,

2001, vol. 24, no. 16), the NuMI facility will be

operational in 2005.

“This work has taken much longer than we

expected,” Bock said. “But since March, when

Healy significantly increased their work force,

progress has been good and we’re looking forward

to starting the follow-on contract toward the end

of the year.”

Precise aim

The manufacturer of the steel pipe will deliver

fifty-six sections, each forty feet long and seven

feet in diameter. Welders have already put together

more than a third of the total decay pipe inside the

NuMI tunnel.

“There is a bunch of things involved to make sure

that the beam goes to the right point in Minnesota,”

said Wesley Smart, the physicist in charge of

NuMI’s alignment. “The contractor is responsible

for putting things in the right place, and Fermilab

surveyors do the quality assurance.”

Physicists expect the center of the neutrino beam

to hit the far detector in Soudan to within forty feet.

To achieve this goal, the alignment of the tunnels

at Fermilab must be exact within a few inches. The

most critical part will be the installation of all beamline

components. Since neutrinos have no electric

charge, it is impossible to manipulate the direction

of the neutrino beam after it has been created.

So far, Smart is pleased with what he has seen.

“Healy’s picked a good surveyor,” he said. “The first

part of the decay pipe is within three quarters of an

inch of the ideal location. That’s what the contract

allows.”

New buildings to come

“When Healy is done with its contract,” said

Plunkett, “the next step is to change the empty hole

in the ground to an underground laboratory, from

a hostile environment into a friendly one.”

A few weeks ago, Plunkett and his colleagues

sent out requests for bidding proposals for the new

contract, which includes the construction of service

buildings on top of two access shafts. The work

is expected to take one year and cost more than

ten million dollars. It includes a service building

that will stand near Fermilab’s main entrance

(see graphic below).

“It will be an industrial-type building with a big hole

—350 feet deep—in the floor,” said Rob Plunkett.

“The building is mostly used for staging. Eventually,

the MINOS detector, one plane at a time, will come

through this space.”

The Main Injector Neutrino Oscillation Search

detector at Fermilab will consist of 280 planes

of steel and scintillator. Technicians are currently

assembling the planes at Fermilab. It is a smaller

version of the detector at Soudan, which is already

under construction and almost half complete.

“So much work has to come together,” said

Plunkett. “It has to grow like an organism.”

Three years from now, NuMI will be all grown up

and ready to run.

“The next step is to change

the empty hole in the ground to an underground laboratory.”

|

The only tunnels required for the NuMI project are a tunnel connecting the

existing Main Injector accelerator to the new target hall, and a half-mile-long

tunnel connecting the target hall to the near detector hall. Miners completed

these tunnels in December.

The only tunnels required for the NuMI project are a tunnel connecting the

existing Main Injector accelerator to the new target hall, and a half-mile-long

tunnel connecting the target hall to the near detector hall. Miners completed

these tunnels in December.

The new approach has had the desired effect.

Since the accident the number of safety incidents

per worked man-hour has dropped by almost

50 percent compared to the first sixteen months

of the project. For Fermilab’s project managers,

however, this is not yet enough.

The new approach has had the desired effect.

Since the accident the number of safety incidents

per worked man-hour has dropped by almost

50 percent compared to the first sixteen months

of the project. For Fermilab’s project managers,

however, this is not yet enough. In April, S.A. Healy began the installation of a

2,000-foot-long decay pipe. The work is part of

Healy’s 30.5-million-dollar contract with the

Department of Energy. It presents the first

important step in outfitting the tunnels with

infrastructure and scientific equipment.

In April, S.A. Healy began the installation of a

2,000-foot-long decay pipe. The work is part of

Healy’s 30.5-million-dollar contract with the

Department of Energy. It presents the first

important step in outfitting the tunnels with

infrastructure and scientific equipment.