|

Fermilab Shutdown Report

9/21/07 – 9/28/07

LINAC

Things Done This Week

- Adjusted Drive Loop on LRF5

- Installed VXI Crates in LRF2, 3 & 1

- Water System Maintenance

- Shutoff All Systems in Preparation for Water Maintenance and Power Outage

- LRF5 Cleaning

- Test Klystron Transformer Oil

- Establish Baseline for HERF LLRF Calibration

- Install VXI Crate in LRF4

- Find Oscillation Problem in LRF4 Modulator

- Repair LRF5 Modulator Weakness.

- Continue LLRF Studies in LRF5

Booster

- Water work:

- Booster 95LCW was recovered after the scheduled CUB power outage last weekend

- All BRF stations and power supplies are currently valved in

- visual inspection showed no sign of leaks

- Monitored the oxygen levels and pressures across the new filters in the tunnel

- Filters were changed out and the correctors were valved in after the oxy levels started declining

- New Booster corrector power supply burn-in started

- polarity checks complete

- correctors have been turned on and run test ramps overnight

- full power test @ 15 Hz

- magnet temperature around 110F

- Additional Activities

- tunnel water leaks repaired

- cable penetration sealing in progress

- installed new injection foils

- RF maintenance is wrapping up

- Next week start up plans

- Proton Source startup is scheduled for October 3rd.

- Coordinating final checks, walkthroughs and clean up in preparation for Oct. 3rd startup

- Booster back to operational keys on Monday, Oct 1st

- Secure Booster on Tuesday, Oct 2nd

- Start turning components on after power outage Oct 3rd

- Goal: Establish beam to Booster dump Oct 3rd

- pending on MI water availability (booster dump line)

Antiproton Source

Mechanical

- Finished D/A, A40, A30, AP3

- D:ESEP, A30 IP fixed; AP3 Pump

- D:ISEP Shielding

- Ion Chamber removal

- Deb DCCT motorized stand

- D:EKIK ceramic tube

- Aligned; Vacuum tight after leak fix

- AP2 Water Hose Replacement

- Leaking LQA replaced

- Replaced leaking Deb Sextuple

- SMA water leak; replaced

- 4 Leak Check (4)

- water leaks to fix

- A10 Obstruction Search

- Components shuffled; aligning

- Brace Skew Quad Coils

Target Station

- Water Systems (2)

- Temperature Monitoring (2)

- Target Rotation

- Storage

- SEM Module

- LVDTs

- In progress

- Sample Retrived

- Lens motion

- Air Exhaust Stack

- 10mm-2 into transformer

- Installed into transformer

- 10mm-3 into transformer

- Lens replacement

- HiPot of PMAG

- PMAG water system flush

- Lens Module water system work

- Power/Emergency Generator Switch

- Elevator table repair

Cryo

- Valve Stem replace

- Leak Check (1 of 2)

- LN2 transfer line maintenance

Cooling Systems

- Deb 3&4 Trans Notch Filters

- Deb Double Notch Filters

- Core 4-8GHz Equalizer

- TWT balance & trip points

- Stacktail Filter 3 cable change

Electrical (Pbar & EE Support)

- Shunt Move

- Shunt Repairs

- PS Maintenance

- Lens SCRs

- Regulation Electronics

- Ion Pump maintenance

- Deb Shunt re-arrangement

- Deb Extraction kicker load adjustment

Other

- Interlocks/Safety System (3)

- Repair cathodic protection

- Holes under buildings

- Water dripping from tunnel ceiling

- Contractor sealed ceiling

- Await good rain storm

- Await contract for filling holes

- DCCT calibration

- Baking System checkout

- RF & TWT filters maintenance

- Lights checkout & repaired

- Acc BPM repairs

- Activation Survey

- Inductance checkout

- PM ODH Fans & Sumps

- Tunnel Wireless

- Install AP2 Leak Detector

- SEM maintenance

- Clogged sump line – Transport

- Berm dug; Replaced entire line; re-established berm; to be surveyed

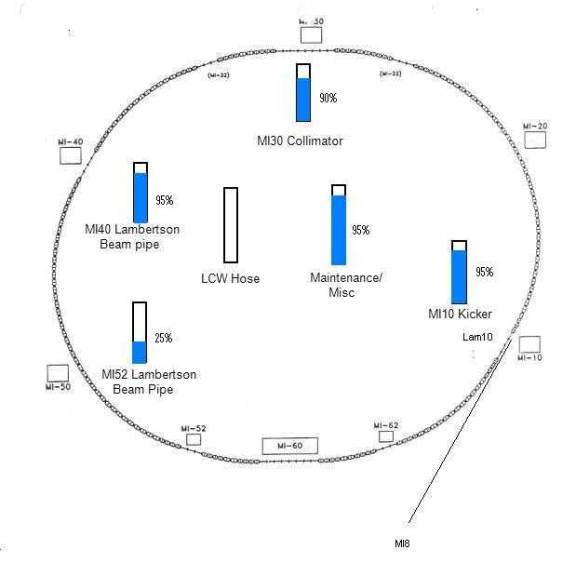

Main Injector

- MI52 Beam tube replacement

- Started replacing upstream beam pipe

- MI40 beam tube replacement

- Beam tubes are replaced and aligned.

- Lambertson bake out is started.

- MI30 collimators

- Completed vacuum connections, leak checking.

- Buss and LCW moves complete. Need LCW hose.

- Installation of magnetic shielding is mostly complete.

- Marble and concrete masks installation is complete.

- Installing and checking controls

- MI Status

Recycler

- Finished or underway

- New DCCT section installed, leak checked and under vacuum

- DCCT section has been aligned

- Beam pipes in this section (between valves) will be baked to 150 degrees C, the DCCT unit will be baked to 100 degrees C, Sept. 21st

- V303 moved, connected

- H308 moved, connected

- STC tank 7 leak check finished

- Second attempt has been made; detected air but found no external leak

- Sublimated TSP’s at STC’s 7,8,9,10.11,12

- Sublimated TSP’s from 204 to 210

- Trombone additional quadrupoles installation

- Installation has been completed

- Measured rough positions of trombone elements with respect to surveyed elements

- Electrical boxes installed for 601-608

- Connections started

- Added support to old DCCT

- Bulk supply upgrade finished

- DCCT cable connected

- Stochastic cooling: Photodiodes aligned

- The 800 transfer line is now leak free!

- MW803 seal has been replaced; leak fixed!

- MW803 survey requested and has been done…(no sticker)

- HP803 (large elliptical BPM) has been replaced with a standard elliptical unit

- Leak free!

- Survey of as-found has been done between gradient magnets

- For the Recycler portion of the transfer line, there is only one large elliptical BPM is left (HP804).

- Jim Fitzgerald has made response measurements for two spare Large elliptical BPM’s

- TOR330 repair under way (Jim/Aisha/Dallas, tunnel part is done)

- BPM calibration has started (Peter Prieto), data of two houses are available

- QCL cable from 301 to 309 has been re-positioned and connected

- Recycler to do list

- Magnet moves analysis finished; numbers ready

- Elevation survey after collimator installation

- Field check for new quadrupoles

- LEP dipole field centering on beampipes

- General vacuum maintenance

- Kicker repair; timing verification

- Diagnostics maintenance

- FW paddles to be swapped out with new units soon

- BLM for scrapers: rebuilding in progress

- Schottky (1.75 GHz) system gain calibration

- Schottky (21 MHz) maintenance

- Laser link vacuum maintenance

- Damper status (in two weeks)

- Safety sign-off (Martin, Sasha)

- Ecool study plan formed

- End-of-shutdown checklist ready (Cons)

- Recycler Start-up plan in progress (Stan)

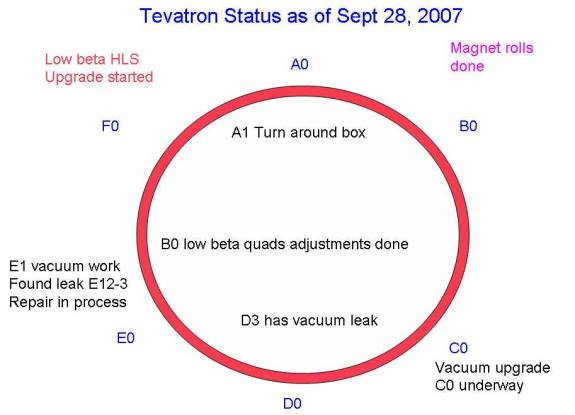

Tevatron

Vacuum Issues

- E12-3 found leak had to pull magnet into isle to fix. Had to repair both ends

- Spool at E12-1 was replaced

- After certification E19-2 failed Hi Pot

- Spool at E19-1 had to be replaced

- A 15 feed can has leak

- If feed can leak fixed then should be able to certify house Friday

- D3 He to air leak fixed

- C0 bake out in progress

SwitchYard

Continuing with maintenance and vacuum work

NuMI

- MI65 emergency power transfer switch repair

- Installed new OTR foil

- Repair PLC Decay Pipe temperature read back problems at Absorber Hall

- Target, Horn 1 & Horn 2 maintenance and upgrades

- Complete Horn 2 RAW upgrades

- Install R blocks over Horn 2

- Remove R blocks over Horn 1 prepare for survey

- Remove Horn 1 RAW water lines

- Start installation Horn 1 RAW pressure gauges

- Install bypass water lines for Horn 1

- Horn 2 suction line repair

- Developed repair and ALARA plans

- Complete initial walkthrough of repair steps at mockup in MI8

- New ceramic and suction line being fabricated

- Locate remainder of repair crew & continue to practice repair plan

- Decay pipe window and helium line installation

- Completed decay pipe window inspection

- Installed 500’ of 1” SS helium fill pipe absorber passageway & hall

- Installed 340’ of vertical SS helium pipe in MINOS shaft

- Developing engineering documentation, shielding assessment addendum, ODH analysis, NuMI note, SAD

- Target pile dehumidification installation project (76% Complete)

- Secured work cell door and removed hardware and supports

- Received & rigged dehumidifiers on to platform on east side of work cell

- Installed dbl walled PVC condensate line in service building

- Completed tie ins of new chilled water piping into CUB

- Continue HVAC & electrical installation

MiniBooNE

- Reverse Horn Polarity

- Take wipes. (week of Sep. 10)

- Reverse polarity of horn power supply. (week of Sep. 17)

- Test horn.

- Check Corrosion Tabs at 25m Absorber (27/28Aug07)

- Change RAW DI Bottle (50%)

- Dry out horn (09Aug07)

- Check Leakage Current on Ion Pumps

- Power Supply Maintenance

MuCool Beamline Installation

- Electrical Work

- Tunnel Work

- Termination of load cables 100% complete

- Termination of the instrumentation 96% complete

- Vacuum instrumentation is 44% complete thanks to B. Brooker and Rosie

- T&M pulled a 480VAC 3-wire cable from the Linac panel to the new MTA disconnect box (PEI room)

- Alignment

- Awaiting on the surveyors to rechecked the beam line components based on the latest beam sheet

- Mostly corrections will be elevation related

- Due to lab priorities, task was delayed a couple of days…

- AMG accommodated MTA job the best they could

- Currently a crew is in the Linac enclosure

- LCW work 100% complete

- All magnets connected to the water manifold and valved in.

- Vacuum work Linac side has priority until Oct 2nd

- Coming along very well…

- 95% spool pieces are made and dry-fit

- Start immediately connecting the spool pieces after alignment

- All ion pumps in the Linac side (2) are installed

- Stand is delivered at the MTA side

- Instrumentation group installed MW cans on the stands

- Magnificent help from Instrumentation group

- Oct 1st and Oct 2nd :

- - Finalize the spool piece connections

Start roughing vacuum as soon as possible

- Concentrate in MTA side after Oct 3rd

- Mechanical installation

- Beam stop assembled, tested and delivered

- Outstanding group effort to meet the deadline

- Awaiting the final alignment of the beam pipe thru the shielding wall and installation of the beam valve in order to proceed with the beam stop installation

- Expect to be complete 9/28

- Shielding installation

- Cable penetration shielding is complete

- Safety can lock the penetrations

- To Do: shielding around the beam pipe

- Awaiting for the beam pipe to be aligned

- Material is available and procedure has been developed

- Oct 1st and Oct 2nd: Finalize the shielding requirements

- for beam operation in Linac

Collider Detector at Fermilab

- both endplugs closed (east last Thursday, west Monday)

- silicon checkout ongoing

- east ISL portcard flow since 9/18, west starting Mon.

- detector elevation survey completed Tuesday

- LBQ realignment Wed./Thurs.

- start flowing flammable gas to wire chambers Oct. 8

- start wire chamber checkout

- 24 hour process system tech coverage

- beginning of 24 hour shift coverage tbd

- other work ongoing (including trigger, DAQ)

D-Zero

Work continues

Alignment

- Tevatron Task Manager: Bocean Field Crew: Bradford,Teafoe, Volk.

- 5496 Re align low beta quads and separators at B0.Date:9/28/2007 1 day 5 man crew

- 5610 Align spool at E19-1 when replaced.Date:9/28/2007 .5 day 3 man crew

- 5572 As found and re survey kicker replacement at F-17. Date:10/04/2007 .5 day 3 man crew

- 5497 Re align low beta quads and separators at D0. Date:10/02/2007 2 day 4 man crew

- Main Injector Task Manager: Oshinowo Field Crew: Wilson, Bradford.

- 5554 4 collimators in the Main Injector at the 301, 303, 307, and 308 locations.

Set limited switches and final checks. Date:10/04/2007 1 day 5 man crew

- Elevation Run Tie Rods & Floor points

- 5528 Ring Wide elevation survey. Date: 10/01/2007-Date: 10/04/2007 4 days 3 man crew

- P-Bar Task Manager: Oshinowo Field Crew: Wilson, O’Boyle, Wyatt.

- 5488 Due to an obstacle search, the opportunity has allowed rearrangement of the devices between quads A6Q1 and A1Q1. Date: 9/29/2007- 10/01/2007 1.5 days 3 man crew

- Numi Task Manager: Bocean Field Crew: Crutcher,Bradford,Wish.

- 5584 Target, Horn 1, Horn 2, as found also old target check. Date: 10/1/2007- 10/03/2007 3 days 3 man crew

- As found the work cell door rails before removal and realign after rail re-installation. Date: 10/4/2007.5 days 3 man crew

- 5585 OTR - after foil is replaced ?

- MTA Task Manager: Oshinowo Field Crew: Wilson, Contract Crew.

- 5470-Final alignment of the MuCool beamline components in the Linac and MuCool Test Area (MTA). See OSheg Oshinowo or Fernanda Garcia for details. Date:9/28/2007- Date:9/29/2007 2 day 3 man crew

- Booster Task Manager:Oshinowo Field Crew: Wilson, Crutcher, Wish.

- 5539 Align new kickers (the new corrector will be aligned at the same time) at long 2 after installation. ?

- D0 Task Manager: Oshinowo Field Crew: O’Boyle,Adkins,Wish / Wilson, J Wilson

- "5523 Final Stickmic closing survey of muon system including CF, EF after detector is closed. This date is preliminary. To be confirmed in late September"

- 5586 V-STAR measurements of positions of south B-layer pixel counters before B-layer walls are opened and after they have been closed. One week or less

- Nova

- 5477-Stake out new Recycler RR30 quad positions for the Nova Project

- 5476-Stake out new Recycler extraction line (MI30) for the Nova Project Accelerator upgrade.

- Civil

- Resurvey of AP 2/3 Enclosure Berm just south of Indian Rd. recently disturbed and backfilled for repair of broken sump discharge line.

- Switch Yard

- Recycler

- 5528 Magnet moves at Recycler V305 and V307.

- BPM in Recycler 800 line HP803 has been replaced with leak-tight unit (serial number 1211). Please verify/align to as-found specs.

Mechanical

Work in the tunnels continues.

Cryogenic System

- Tevatron at LN2 temperature except A1 and E1 at room temperature.

- Pbar Debuncher Stochastic tanks and S/C Notch Filter dewar were warmed up to LN2 temperature in anticipation of system purification next week; 50 ppmN2 contamination released.

- Tunnel magnet cryostat vacuums at A25 and D35 regions are still of concern; D35 air-vacuum leak found, fixed, and in process of certification by AD/MSD.

- 3 FRIG Mycom comprs (plus CDF & DZero) running with helium precooled to LN2 temperature flowing through magnet strings.

- CHL helium inventory management system operating on clean Helium Tank Farm, though A0 GHe Recovery being vented until Mobile Purifier is back online. CHL Main Helium Purifier was derimed, cooled down, and put back online to Screw Comprs. CHL Mobile Helium Purifier was taken offline, derimed at room temperature, and will be cooled down back to service today.

- CHL Nitrogen Reliquefier (NRL) plant off and LN2 supply dependent on vendor deliveries to CHL LN2 dewar tanks; deliveries are fine. NRL IR Booster compr startup problems being addressed; starter fixed but oiler problems exist.

- CHL 24/7 operations shiftwork resumes Monday Oct. 1.

- FRIG Maintenance in progress

- 13 of 13 wet expander flywheels have been replaced.

- 26 of 26 wet/dry expander overhauls of cold ends are completed (as well support for CDF & DZero expanders).

- Various vacuum, instrumentation, and controls maintenance continuing.

- Mycom compr startup checkout completed with 28/31 available.

- CHL Maintenance in progress

- Coldbox-1:

- Vacuum systems being restarted.

- System purification being started.

- NRL plant:

- Subsystems startups in progress.

- Various compr and facility maintenance in progress

Controls

- Recovered from Weekend System Outages

- UPS Shutdown Multicast Testing

- Applications and Device Database Updates – Complete

- SDA and Save & Restore received newest Sybase update as well

- TCPORT process port to Linux – Complete

- Central Processes port to Linux finished

- MI-30 Collimator Controls Installation & Test

- Assorted Linac Controls Upgrades

- VME node 0602 Timer & Beam Inhibit Upgrade

- Low Energy RF ON Trigger Reconfiguration

- Linac Tank 1 Collimator Controls

- Booster RCC VME Node Scope Trigger Upgrades10/3/07 Recover from Sitewide Power Outage

- NuMI Decay Pipe RTDs

- 10/3/07 Recover from Sitewide Power Outage

FESS

- Pi Poles - 345KV Transmission lines to MSS

- Power Up 345 KV lines on 9/29/07 into MSS yard only.

- Scheduled site outage/MSS energizing on 10/3/07

- Casey’s Pond

- OPERATING on the 400HP PUMPS [still flowing thru 14 inch strainer].

- C-4 ICW Pumps on standby.

- ICW FLOW METER WIP. Expected transfer back to the 16 inch strainer on Mon 10/01/07.

- New ICW liquid Bromine injection treatment started this week.

- CUB SHUTDOWN 9/22 & 23

- FDR 42 – Servicing 13.8KV switches from Giese Rd to CUB was completed. A major finding was the infiltration of sand from the building painting preparation into the switch housings. This led us to the re-inspection of Booster E/W switches that required cleaning.

- Servicing 13.8kv/4160v – 480v unit sub-stations/transformers for CUB. No findings.

- Servicing electrical 480/120v panels/switches inside CUB. No major findings.

- DDC work – control wiring/upgrades/system checks. No major findings. PBar pump valve control actuators were installed for improved LCW pump start ups.

- Cooling tower sump/tank check. Very clean.

- PBar S/T heat exchanger [HE-8] is at end of life. Eddy current testing shows up to 30% of its tubes are over/at/near the 50% thickness factor [15 leaking tubes were plugged]. This is the back-up exchanger for the P/F HE-9.

- Sunday start up on time [5:00PM].

- CRAFT SD STATUS

- Shift Work to Resume starting 12:01 AM Monday 10/01/07.

- Electrical craft work backlog remains high.

- Most of the Mechanical work is completed.

- HVAC is completed.

- FINDINGS – can review at the last meeting.

- Tevatron Silt and Extension Collars

- All Suction screen extensions [21] are installed and all of the screen cleaning/maintenance is completed.

- Two Pond Pump Intake valves [A-2 & D-1] were replaced.

- OTHER WORK

- CUB – 55LCW PUMP REPLACEMENTS WIP. LP 4 is completed & on line. LP5 is installed & will be commissioned by end of next week. Will require a 55 LCW short shutdown/pump switch to finalize project.

- TENTATIVE SITE ICW FLUSH SCHEDULED TO START Mon 10/01/07 THRU 10/07/07.

- ZEBRA MUSSEL TREATMENT SCHEDULED FOR MID-OCTOBER.

- Wilson Hall FIRE PUMP RUN [ICW] test to be scheduled by end of October to satisfy DOE requirements.

Safety

- Safety System Status

- Upgrade M02 - M05 Enclosure Interlocks 90%

- Upgrade M01 Enclosure Interlocks 100%

- Upgrade Main Injector PLC Code and replace PLC Batteries 100%

- Replace Pbar Vault Key Tree Door Latches & add status LEDs 100%

- Upgrade Meson Area Oxygen Monitors 10%

- Replace Safety System DEC talk with ATT Natural Voices 30%

- Modify Linac Enclosure Interlocks 100%

- Linux kernal 2.4 to 2.6 upgrade to Safety Data Acquisition System 100%

- Route Key Tree release signals from MCR to Meson 100%

- Install Radiation Monitor Cables for the Muon Test Area 100%

- Replace oxygen monitor cells in the Tevatron 100%

- Radiation Exposure

- ~1.4 rem total dose for the seventh week of the shutdown.

- ~7.4 rem accumulated dose for the shutdown.

- Startup

- NTF Safety System testing completed 9/27

- Linac Safety System testing completed 9/27

- Booster Safety System testing tentatively scheduled for 10/1

- 8 GeV Line Safety System testing tentatively scheduled for 10/1

- A successful shutdown is getting our work done safely

Accelerator Update Archive

More Information

For Tevatron luminosity charts and the current status of Fermilab's accelerators and detectors (live!), please go to Fermilab Now.

Comments and Suggestions

What do you think about the Accelerator Updates? Please send comments and suggestions to: accelupdates@fnal.gov.

|