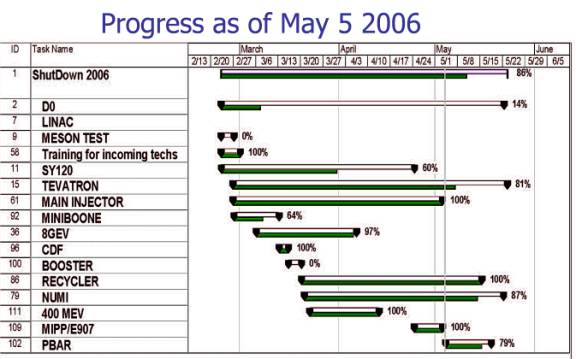

LINAC

April 28 – May 5

- Finished all Driver and 9” Line LLRF Characterization Measurements

- STILL RECOVERING FROM LAST POWER OUTAGE! LRF5 has been experiencing a multitude of problems, starting with the driver and now the modulator. Work is ongoing

- H.E. LINAC Klystron systems are running

- H.E. Debuncher Water System Temperature and Pressure Calibration completed

- NTF Patient Treatment (Th & F)

May 5 – May 12

- Characterized LRF3 and LRF4

- Replaced the Power Amplifier in LRF3 (it was sparking)

- Replaced 4616 Driver In LRF4

Remaining Work

- Today or Monday – Install Motor Drive for 10 MeV Collimator (Tested & Ready)

- Hopefully have LRF5 Repaired in order to run 400 MeV Beam in the LINAC

- Repair Ground Fault & Driver on LRF7

- NTF Patient Treatment (M, W, & Th)

Booster

- MI-8 Dump cable pull finished

- Terminating/Connecting Cables Upstairs

- Finishing ACNET/controls work

- Kickers Tested

- Tunnel Cleaned

- 400 MeV/ORBMP

- Vacuum pump down continues

- Final Alignment Finished

- PS testing ORBMP (Today?)

- Polarity/PS Testing Continues

- RF repair/maintenance continues

- Long 13 extraction elements removed

- LCW up to full pressure (two pumps)

- Booster Door Cores Changed back – Search and Secure Tested (Last Night – no problems)

Schedule

- MI-8 Dump on schedule – (tasks remaining)

- Test Dump Switch, Septa (Turn on supplies)

- Finish Safety System connections

- ORBMP – Finish PS work/testing

- 400 MeV PS/Polarity Testing

- RF work – Connect up Anode & 480

- GMPS - Hipot and Testing

- Safety System checkout (Start of Ctrl Access)

- Walk Through, Search and Secure, Sign Off

- Beam Start-up (DC beam end of next week!)

Dogleg as it once existed

Dogleg Gone

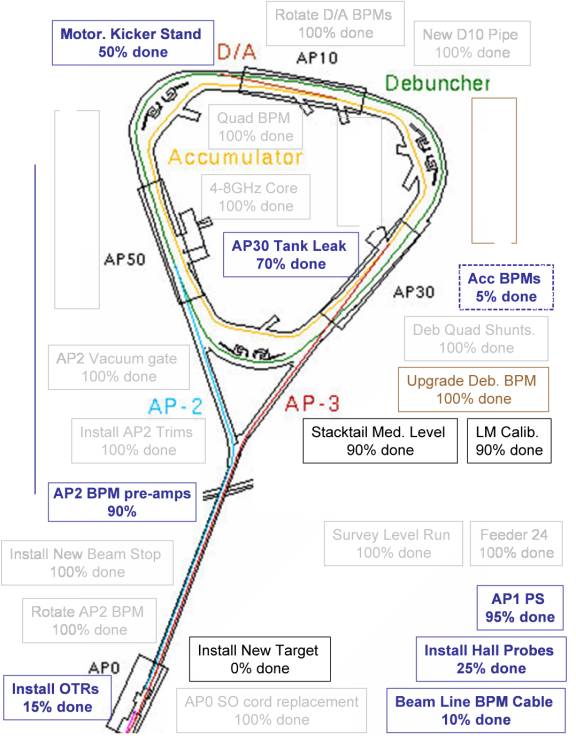

Pbar

On Schedule

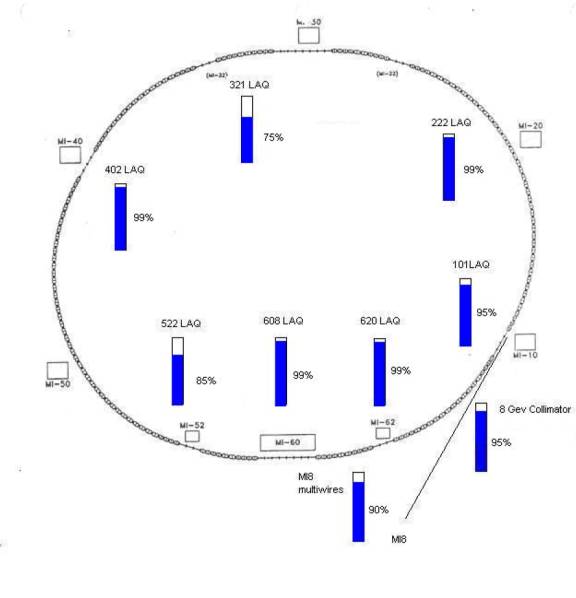

Main Injector

- Continued vacuum repairs in the MI8 line.

- Completed vacuum repairs at 620.

- Completed Lambertson bake at 101.

- Completed installation of large aperture quad at 521,522.

- Began Lambertson and beam pipe bake at 521, 522

- Completed installation of the MI10 kicker cooling system.

- Began installation of large aperture quad at 321.

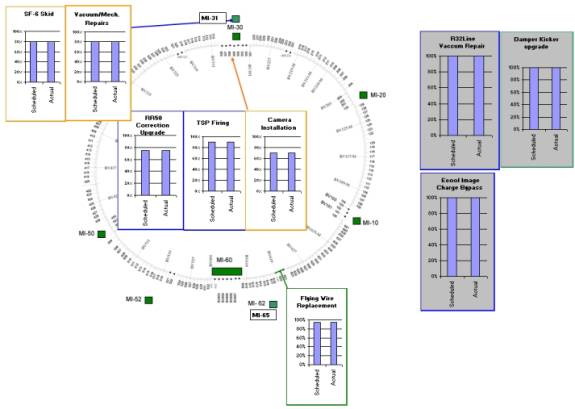

Recycler

- Flying Wire Installation

- Reconnecting tunnel hardware

- Testing of the system is underway

- Other instrumentation in this region will need to be connected (i.e. BPMs)

- Damper Region Q527-Q601

- BPMs need to be reconnected -Done

- Dampers need to be connected/Testing may commence

- SF6 skid replacement - 80% complete

- Pipe fitting will be completed today

- What is left to do?

- Engineering note for pressure vessel (heat exchanger, blower, dryer, etc.)

- EIT process system still needs to deliver/install heat controls for dryer system

- Testing and filling of system by mid to end of next week

- Operational permit shifts to end of next week and on to the week beginning on the 15th.

- Gun modulator repair and testing -60% complete

- Venting up gun acceleration tube

- Replace TSP -Done

- Replace Ion Gauge -Done

- Inspect Electron gun -Done

- Measure Magnetic Fields in cathode section –Done

- Replaced OTR in Deceleration line –Done

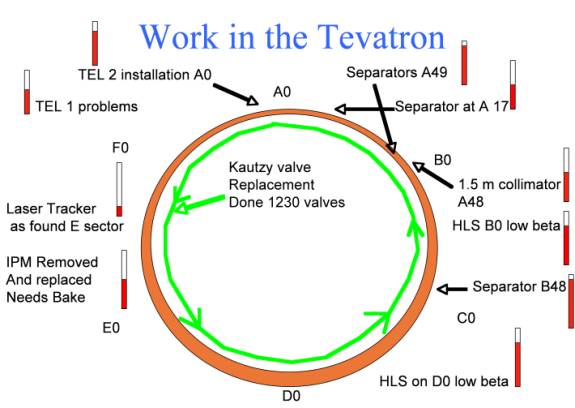

Tevatron

Jobs in Process

- B side of low beta quads at B0 are done

- AQ5, AQ2, and A side separators done

- AQ4 has been bumped by 0.5 inches

- Will align AQ3 and AQ4 Monday

- HOPs cable pull

- A3 conning tower replacement underway.

SwitchYard

Work continues, but there may not be time to install the quadrupole at A0.

NuMI

- Horn 2 Pulsing Delayed due to Work on the TR-MI65B 13.8 Switch

- Target Chase Chiller Delivered Yesterday – Reconnect Next Week

- Prism Duct Work for Desiccant Dehumidifiers Progressing Well

- Scaffolding Erected for Duct Connection to Bottom of SR3

- Exercised Target Motion Control and Checked Positions

- RAW Lines, Flow Meters and Valves Installed for Target Carrier

- Improved Grounding of Chase Components to Horn Power Supply

- Condensate Tank Pump Repaired – Install Next Week

- Beginning Rework of VESDA Air Sampler Exhausts

- Target Hall to Pre-Target Hatch Covers Reinstalled

- Planning For Safety System Tests May 26

- Planning to be Ready to Accept Beam on May 27

MiniBooNE

- RAW System:

- Complete (really, this time).

- Desiccator:

- Change air filter by end of next week.

- Alignment:

- Realign triplet on Monday (May 8).

- Water Leak on Q866!

- New item (not scheduled – sorry).

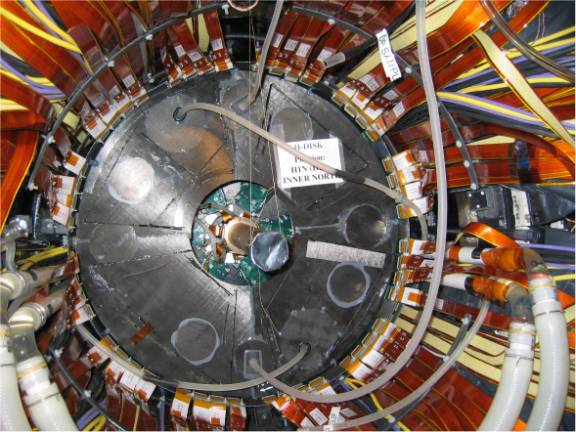

Collider Detector at Fermilab

On schedule

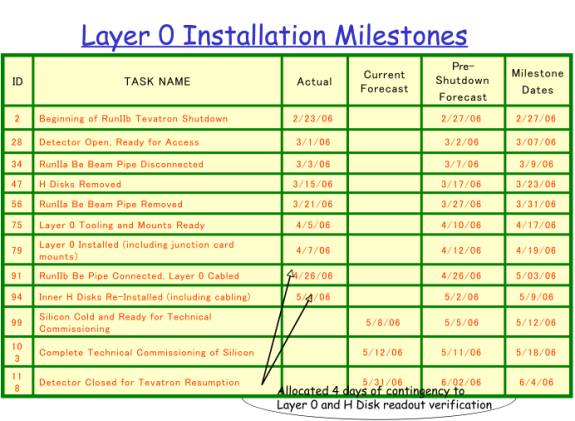

D-Zero (D0)

- Site Wide Power Outage (and Recovery)

- 0700-0730 Monday

- Power down detector in advance

- Two BLS power supplies failed to recover

- Layer 0

- Re-install north inner H disks

- Re-cable inner H disks and connect up cooling

- Verify inner H disk readout

- More inner H disks channels appear to be functional now than when disks were dismounted in March (due to the hard work of the installation & readout teams)

- Install beam pipe support

- Make spool to EC beam pipe joint

- Level 1 Calorimeter Trigger

- Complete LVDS cable installation

- Test transmission from ADF to TAB

- Continue firmware debugging/development/verification

- Level 1 Central Track Trigger

- Refining monitoring tools

- Exercising trigger system

- Detector Maintenance

H Disk

Beam Pipe Support Installed

Mechanical

Work Continues

Cryogenics

Cryo Operation

- Tevatron at LN2 temperature and LN2 usage is stable with vendor deliveries running only 2-3 truckloads per day due to the Tevatron being 1/6 at room temperature. Helium losses are slightly down at 12 kscf/day (1/3 of normal during TeV operations); some helium being replenished from A0 GHe Recovery of test caves.

- A1 and A3 are at room temperature and isolated with LOTO.

D1 and F4 are also at room temperature, have been reconnected by Cryo, and are under helium flow. D1 cooldown permit signoff has been completed and cooldown to LN2 temperature will commence soon.

F4 cooldown will wait until TEL-1 is re-installed.

A3 has been completed by MSD, but spool piece conning towers retrofit by TD is in progress.

- Pbar D60 Debuncher tanks were cooled down to LHe temperature after Division sign-off.

- ACNET application programs relating to FRIG operations continue to be tested on Linux consoles.

- Nitrogen Reliquefier plant was started and cooled down successfully. It was shut off later for some minor repairs and due to lack of sufficient nitrogen gas coming from Tevatron due to E0 still being on generator power. We plan to cool it down again next week.

- CHL Helium Compr “C” was started for testing and purification but was shut down due to 2 nd stage suction cylinder valve failure.

- MCR monitoring cryo operations.

CHL Maintenance:

- General facility maintenance is in progress, including testing of relief valves per FESHM.

- Helium Compr “A” cooling tower installation has been completed and system testing has started. The motor switchgear mechanical binding needs to be addressed by FESS.

- Helium Compr “D” overhaul is almost completed but awaiting installation of cylinder valves.

- Helium Coldbox-2 controls upgrade is in progress.

- Mobile Helium Purifier is being derimed at room temperature and piping modified

FRIG Maintenance:

- Various FRIG bldg vacuum maintenance and instrumentation repairs (e.g. lost charge on VPTs) are in progress, as well as support work on houses at room temperature and other equipment as things fail even during the shutdown period.

- Various Mycom compressor maintenance: leak hunting and general repairs.

- Wet expanders overhauls have been completed ring wide.

- Reciprocating cold compressors are being overhauled for A4, B1, and C4.

· Kautzky relief valves have been replaced ring wide and re-torquing clamps are in progress. One KV at A3 was found with broken poppet tip that was blown into the helium suction header, though this KV still functioned properly.

- Helium to atm leaks on conning tower quick-disconnect fittings and safety lead flow glands are being found and fixed.

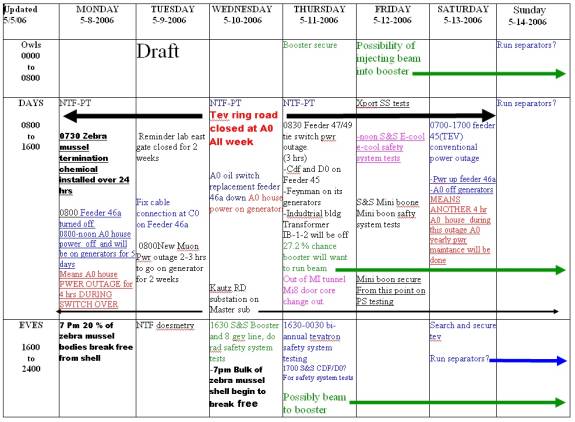

Facility Engineering Services

- Zebra mussel cleaning to begin on May 8 and continues, at a minimum, until May 20.

- CUB: 95 LCW backup pumps not ready yet

- Soft starts not ready for Pbar yet

Instrumentation

Work continues.

RF

Work continues.

Controls

Work continues.

ES&H Upgrades

Safety System Upgrades

Keep discussing safety with your crews to keep our focus on getting our jobs done safely.

- Booster 80% Complete

- Booster Staging Area gate interlock work complete

- Booster Dump Move Configuration Changes

- LG1 area work continued

- Booster logic module configured and wired

- New 809 beam stop and V809 magnet contactors installed and wired

- Need to reconnect the 4 Booster radiation monitors moved for the

communication duct installation and new switchgear installation.

- Booster Electrical Safety System testing completed last night

- Documentation submitted to ESH Section for Approval to Operate

- Main Injector 45% Complete

- MI-8 Electrical Safety System testing completed last night

- Lower Level Controlled Access Displays Replaced

- MI-62 & MI-30 complete. 5 Buildings left.

- P-Bar Source 100% Complete

- Safety System Power Supply & Junction Box Replacements

- Interlock New BSC700 Beam Stop

- Tevatron 98% Complete

- F-Sector Radiation Monitor Card Replacement

- MT6 Section 1 & 2 70% Complete

- Enclosure Interlock System Upgrade

- Safety System Testing

- Booster Radiation Monitors Monday

- P-Bar Radiation Monitors Monday or Tuesday

- MI-31 and Pelletron CDC Wednesday 1300

- Booster Critical Device Controller for Booster Dump operations

Wednesday 1700

- Tevatron enclosure interlocks Thursday 1800-0000

- Transition to Operations

- Don’t let schedule pressures influence working safely.

- Monitor overtime usage to prevent employee burnout.

- Continue to emphasize safe work practices to our crews.

EE Support

Work continues

Alignment

- Tevatron

- Complete Elevation run B sector Floor only

- Scheduled CDF Low Beta Alignment (This week)

- Scheduled TELL 1 Alignment

- Main Injector

- Recycler

- 8Gev

- Completed BPM Alignment to continue.

- Scheduled To Re-Align magnet moved (Today)

- P-Bar

- Completed Girder Check

- Scheduled ceramic beam tube alignment

- Scheduled deep rod installation

- MiniBooNE

- Completed As Found list

- Scheduled Magnet moves (Monday)

- NuMI

- Completed Re-Survey Multiwire and OTR.

- Scheduled Horn check. (Today)

- Booster

- Alignment of new primary collimator

- 400Mev

- Add Ons

- D0 - Make Level-Run vertical measurement of select Collision Hall monuments West Wall

- Main Injector Align barrier cavity at MI604 location. Completed

- Fess - the Batavia Rd. Guardhouse project. Completed

- Fess - MI Ponds C&D project will replace existing manholes and pipe.

- Switchyard - Check the alignment of elements in Switchyard manhole enclosure F3.

- CDF Scheduled CDF Low Beta Alignment

- 8Gev Magnet re-alignment Moved Completed

- 8Gev Elevation run (Wednesday) Completed

- NuMI Target Hall check for deformation

Schedule for Next Week

Accelerator Update Archive

More Information

For Tevatron luminosity charts and the current status of Fermilab's accelerators and detectors (live!), please go to Fermilab Now.

Comments and Suggestions

What do you think about the Accelerator Updates? Please send comments and suggestions to: accelupdates@fnal.gov.

|