|

LINAC

March 24 - 31

- Continue Preventative Maintenance on H.E. LINAC Klystron Systems

- Returning LRF7 to 7835 Conditioning

- Driver Characterization on LRF5

- Anode Bulk Supply Upgrade

- MuCool Alignment Scheduled Today

- NTF Patient Treatment (M, W, & Th)

March 31 – April 7

- Continue Preventative maintenance on H.E. LINAC Klystron Systems

- LLRF 9” Line Calibration on LRF4

- Modulator Characterization on LRF5

- I- Anode Bulk Supply Upgrade

- NTF Patient Treatment (M, W, & Th)

Completed Work

- Cleaned L.E. LINAC Modulators & Rectifiers (LFR1-LRF5)

- Replace water fittings in Klystron Modulator De-Q’ing circuit

- Replaced Collimator between L.E. LINAC Tanks 1 & 2

- L.E. LINAC Water Maintenance

- Modified Chopper & Moved Quad for future MuCool operations

- Cleaned Filters on 8 Ion Pump PS’s

- 45°/90° Magnet PS Maintenance

- LLRF 9” Line Calibration on LRF5

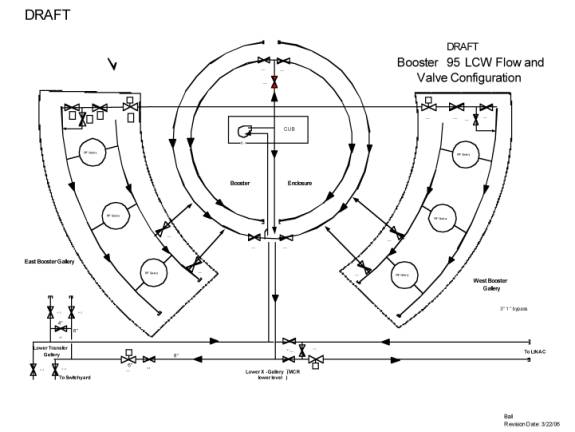

Booster

- Dump and shielding installation completed

- Q805/Q806 re-installed, Septum in place

- Need to align quads and septum before Beam pipe installation

- Continued Kicker installation

- LCW pipe for corrector upgrade nearly done

- ORBMP magnet/Girder work delayed but progressing

- ORBMP Power Supply Conditioning

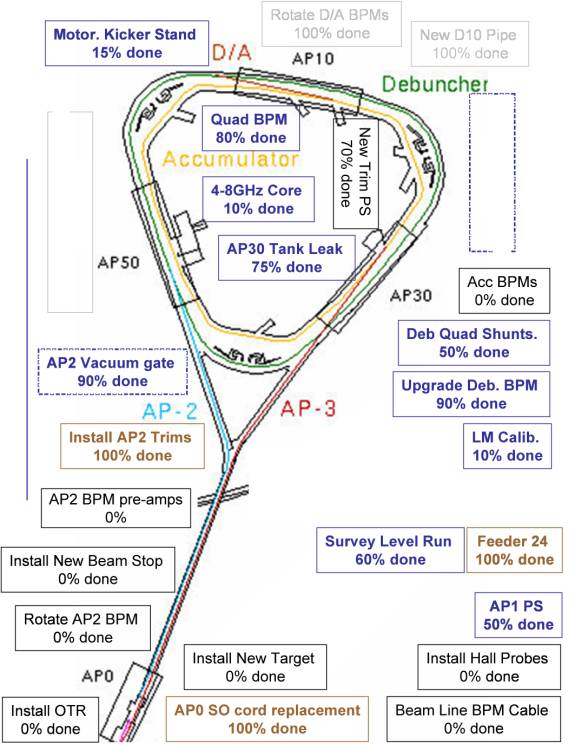

Pbar

On Schedule

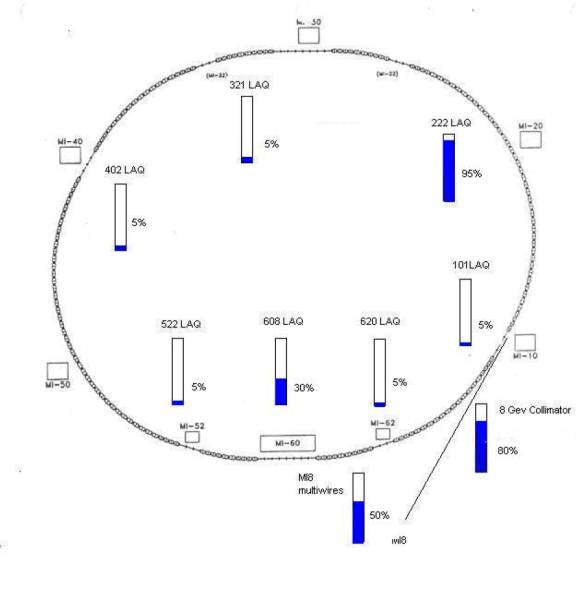

Main Injector

- Continued installation of new MI8 line multiwires.

- Continued installation of MI8 collimator.

- Continued installation of MI10 kicker cooling system.

- Continued installation of a large aperture quadrupole at 222.

- Began installation of a large aperture quad at 608.

- Began installation of a large aperture quad at 620.

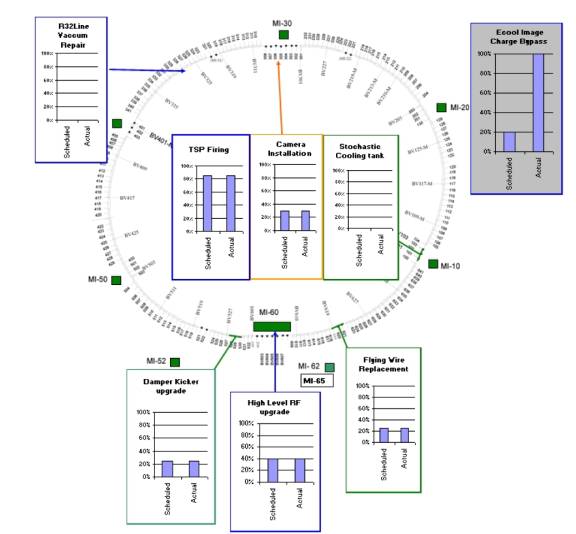

Recycler

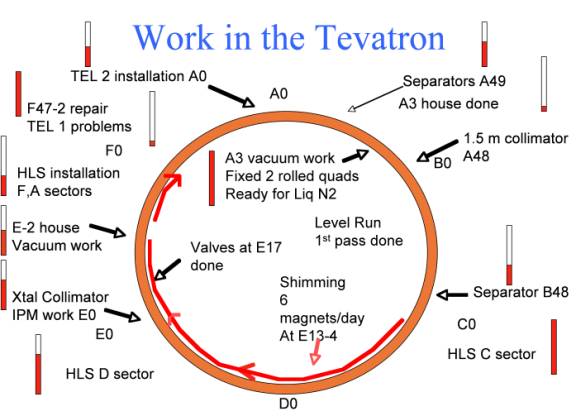

Tevatron

Progress

- F4 and A3 vacuum work done, walk through complete today

- A 49 separators installed and under vacuum need to do power test before bake

- B48 separator installed needs alignment

- C0 HLS system done

- D0 HLS system needs final test

- Shimming on schedule in F sector skipped 11 magnets in E-2 to make way for vacuum work

- E2 found one bad bellows and one bad seal finish next week?

- TEL 2 in place TEL 1 at VMS getting cut open

SwitchYard

Shutdown work continues.

NuMI

- Target Hall Crane Hoist Brake Again Operational

- Completed More Detailed Map of Horn 2 Residual Radiation

- Developing ALARA Plan for Horn 2 Repair

- Checked Feet for Horn 1 – Found Not to be Loose

- Cleaned Flaking Nickel Coat from Horn Stripline Blocks

- Target Chase Chiller Modifications Progressing at Manufacturer

- Scaffolding Construction for Drip Pan Removal Complete

- Pan Removal Scheduled for Next Week

- Drain And Calcite Cleaning Completed in Pre-Target & Target Hall

- Target Hall Air Damper Replaced – Air Leaks Minimized

- Beginning Installation of Fall Protection in Pre-Target

- NuMI Water System Again Operational

- Pump Aligned and Miscellaneous PM

MiniBooNE

- This week: No work scheduled.

- Test Horn week of April 10:

- Need LCW.

- Need enclosure interlocked.

- Begin alignment work.

D-Zero (D0)

- Layer 0

- Reconfigured north end of detector to extract Run IIa beam pipe

- Removed Run IIa beam pipe from Collision Hall

- Transport Layer 0 to Collision Hall

- Load Layer 0 and Run IIb beam pipe into EC north beam pipe

- Level 1 Calorimeter Trigger

- Move L1Cal trigger crates from sidewalk to MCH1

- Continue routing BLS cables to patch panels

- Level 1 Central Track Trigger

Mechanical

- Current Status

- Valves required for flow have been verified open

- A temporary stand down on all main header valves is in place.

- LCW System Operational, half capacity

- Booster Flow, Enclosure, Gallery, restricted

- Switchyard and LINAC normal configuration

- Temporary Configuration Control procedure in place, Lock box

- 1st Draft Call and Approval List

- Short Term

- Configuration Control/LOTO for normal shutdowns

- Identify and operation control all main header valves.

- Procedure for emergency situations

- Mid Term

- Water relief valves upstairs & downstairs

- Surge tanks

- Review & Update console graphic page ACNET Console, Improved instrumentation pressure/flow

- LCW System Configuration training (operators & water techs)

- Rookie books

- Long Term

- Piping System Reconfiguration

- Add bypass in CUB (FESS) or downstairs or gallery (AD)

- Valve Position Monitors/Indicator

- Actuate critical valves for control

- Very expensive. Cost versus value, time labor

Cryogenics

Cryo Operations

- Tevatron at LN2 temperature and LN2 usage is stable with vendor deliveries. Helium losses are slightly up at 13 kscf/day (1/3-1/2 of normal during TeV operations).

- A1, A3, and E2 are at room temperature and isolated with LOTO. F4 has been completed by MSD and currently being restored by Cryo Dept with anticipation of final walk-through and sign-off early next week; this house can be cooled down to LN2 temperature without the TEL-1 installed. A3 is also almost completed by MSD; Cryo may epoxy past noted helium leaks on power leads and spool piece conning tower leaks need addressing.

- Pbar D60 Debuncher vacuum work has been completed by Pbar Dept, thus Cryo personnel will restore helium/nitrogen connections and cool down tanks to LN2 temperature next week.

- ACNET application programs relating to FRIG operations are being tested on Linux consoles.

- MCR monitoring cryo operations.

CHL Maintenance

- General facility maintenance is in progress.

- CHL Helium Compressor “A” cooling tower installation is continuing with anticipated completion by month end; required piping passed pressure test and radiography. Some minor electrical/instrumentation work is left.

- NRL maintenance is in progress. The IR Booster Compressor was overhauled (one piston rod needed repairs). The TSI Compressor Niagara Intercooler heat exchanger bundles were cleaned, leak checked, and over a dozen leaks were fixed with brazed patches; plans are to reinstall the Intercooler next week. Estimate return of plant back to service is after the April 3 MSS power outage.

- Helium Coldbox-2 controls upgrade is in progress.

FRIG Maintenance

- Ring-wide overhauls of wet expanders in progress with 13/24 completed.

- Tevatron Cryogenic Transfer Line E4-F1 air-to-vacuum leak at F1-end bellows was repaired successfully. However, two plate relief valves (D4-E1, A1-A2) on the TRL LN2 circuit were lifted and thus required depressurizing and thawing for resealing.

- Five IHI cold compressors were removed for inspection and are being overhauled.

- Various FRIG bldg vacuum maintenance and instrumentation repairs (e.g. lost charge on VPTs) are in progress, as well as support work on houses at room temperature and other equipment as things fail even during the shutdown period.

- Various Mycom compressor maintenance is in progress: leak hunting and general repairs, F0#1 compressor replacement, F0#3 motor starter replacement

Facility Engineering Services

Have collected more mussels.

Instrumentation

Work continues.

RF

Work continues.

Controls

Work continues.

ES&H Upgrades

Safety System Upgrades

- Data Acquisition System 95% Complete

- 16 of 17 Linux Ethernet Port Replicator (LEPR) chassis installed

- Booster 40% Complete

- Remove RDF Area

- Booster Dump Move Configuration Changes

- Main Injector 15% Complete

- Lower Level Controlled Access Displays Replaced

- Main Injector Coasting Beam System changes

- Lam10 Critical Device Interface Installation

- P-Bar Source 60% Complete

- Radiation Monitor Card Replacement

- Safety System Power Supply Replacement

- Interlock New BSC700 Beam Stop

- Tevatron 50% Complete

- Moving location of both Tevatron Coasting Beam Gate Valves

- MT6 Section 1 & 2 30% Complete

- Complete Enclosure Interlock System Upgrade

- Safety System Testing 0% Complete

- All areas need to be re-tested before startup.

- ~3.5 R total dose for the first 3 weeks of the shutdown.

- Reminder to get weekly dose cards or electronic dose recording turned in on Monday’s.

- No Injuries or Incidences report.

EE Support

No Report

Alignment

- Tevatron

- Completed A49 Separators

- Completed Rough Align Tell II

- Completed Bypass Alignment (Tell II) (Miscellaneous Components)

- Completed 40% Unrolls

- Completed Tie-Rod Elevation run 50%

- Scheduled B48 Separators (Today)

- Scheduled Unrolls

- Scheduled Deep Rod installation.

- Scheduled TEL II, TEL I support.

- Main Injector

- Completed Alignment MI 222

- Completed MI 321 Quad and adjacent Lambertson

- Completed MI 521-522 Quad and adjacent Lambertson

- Scheduled MI 608

- Scheduled MI 620

- 8Gev

- Completed 4 Collimators at CB836 and CB838.

- Scheduled " The installation of the MI-8 beam dump will require alignment. Several kickers will be installed, one septa magnet, 1 BPM, 2 Toroids, beam pipe, 1 quad will be moved and two multiwires."

- P-Bar

- Completed 90% Elevation runs (Drops are still needed)

- 400Mev

- Recycler

- Scheduled 180 Deg. Magnet alignment and beam pipe.

- MiniBooNE

- CDF

- Linac

- Scheduled Align changes to upstream 400 MeV line in Linac enclosure, Q74

- MIPP

- Completed 90% of requested as found.

- Add Ons

- Completed as found E21-2

- Completed as Set E21-2

- Scheduled Tevatron Unrolls

Accelerator Update Archive

More Information

For Tevatron luminosity charts and the current status of Fermilab's accelerators and detectors (live!), please go to Fermilab Now.

Comments and Suggestions

What do you think about the Accelerator Updates? Please send comments and suggestions to: accelupdates@fnal.gov.

|