|

LINAC

March 10 - 17

- Started Preventative Maintenance on H.E. LINAC Klystron Systems

- Tune-Up of RF stations LRF1 to LRF3

- Diagnose Various LE Quadrupole Problems

- NTF Patient Treatment (M, W, & Th)

- LLRF Characterization on LRF5

- Anode Bulk Supply Upgrade

- 45°/90° Magnet PS Maintenance

- Return L.E. LRF7 Back to 7835 Tube Conditioning from MuCool 200 MHz Cavity Conditioning

- MuCool Alignment planned for today

March 17 - 24

- Continue Preventative maintenance on H.E. LINAC Klystron Systems

- Investigate Q3Bulk Supply

- LLRF Characterization on LRF5

- Anode Bulk Supply Upgrade

- NTF Patient Treatment (M, W, & Th)

Completed Work

- Cleaned L.E. LINAC Modulators & Rectifiers (LFR1-LRF5)

- L.E. Water Maintenance

- Modified Chopper for MuCool

- Cleaned Filters on 8 Ion Pump power supplies

Booster

- Dump and Shielding installed

- MI-8 quads re-installed

- Starting Kicker installation

- LCW pipe for corrector upgrade nearly done

- ORBMP magnet issues – delaying install

- MI-8 LEP corrector coils replaced

- One transformer replaced – more next week

- RF maintenance continues

- Still waiting on MI-8 conduit!

- Big hole outside BWT getting bigger

Reminder

- 13.8KV Transformer/Switchgear Replacement

- Prepare for next week's transformer/switchgear work

- 208V work

- Schedule for power outage and switch to generator 0700 to 12:00 for electrical work and switch over to generator

This will affect BWT, BWG, MuCool and Booster Tunnel

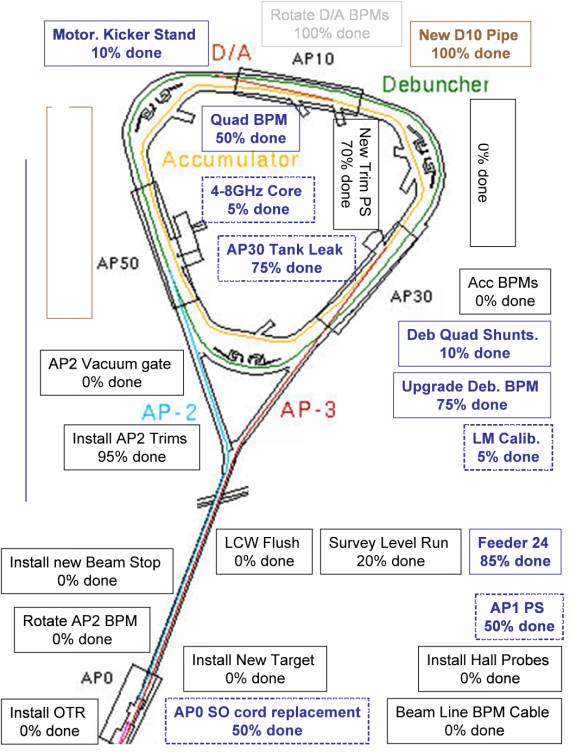

Pbar

On Schedule

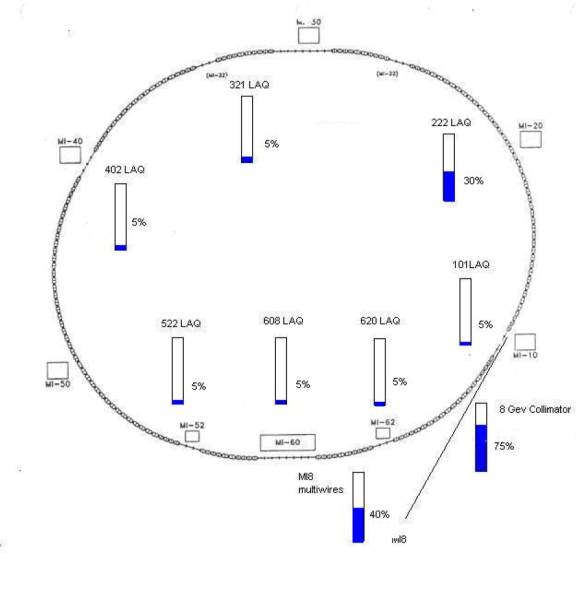

Main Injector

- Began installation of new MI8 line multiwires

- Continued installation of MI8 collimator

- Continued installation of MI10 kicker cooling system

- Replaced LEP correction elements in MI8.

- Began measuring BPM cable attenuation.

- Began installation of a large aperture quad at 222

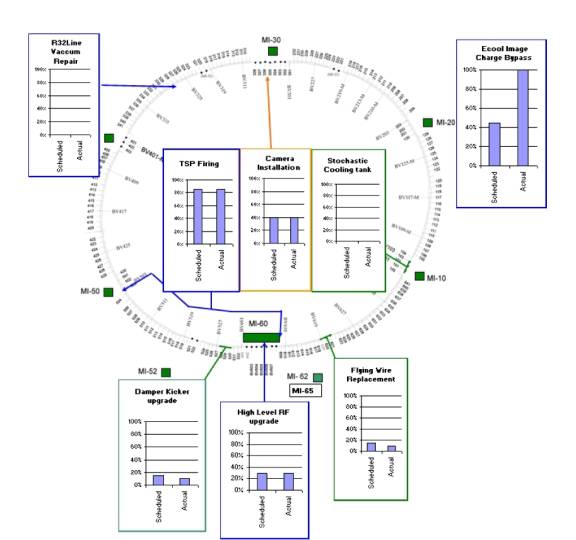

Recycler

The major work is the on the kicker and the Flying Wire

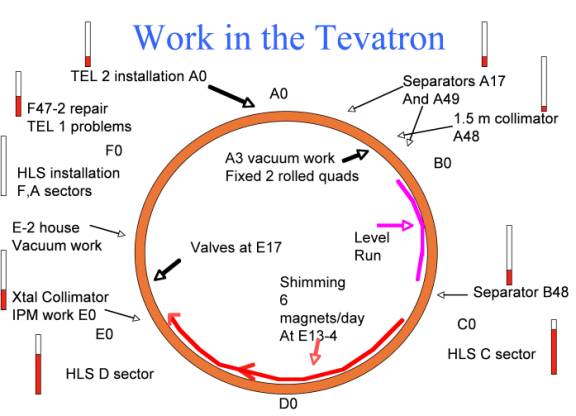

Tevatron

Progress

- Kicker at A0 back in place

- TEL1 removed from TEV sent to IB2 trying to determine where He to vacuum leak is

- Quad at A38 replaced and quad at A39 unrolled

- Separators landed at A49 survey underway

- C and D sector HLS plumbed in and tested

- Crystal collimator installed bake out underway

- Valves installed at E17 flying wire

- Replaced Spool at F47 certifying house

SwitchYard

No Report

NuMI

Optimistic for Repair of Horn 2 Ceramic Break

- Radiation Mapping Horn for ALARA

- Starting to Develop Work Procedures

Target Hall Crane

- Target Hall Crane Hoist VFD and Hoist Brake Repaired

- Target Hall Crane Hoist Brake Failure

- Repairs Starting This Morning

- Scaffolding Construction for Drip Pan Removal on Hold

Misc.

- Drain And Calcite Cleaning Started in Pre-Target

- Pre-Target to Target Hall Air Leaks Sealed

- Beginning Installation of Fall Protection in Pre-Target

- 20 KW Quad Power Supply Current Regulator Modifications Progressing

- New Motor Operated 13.8 KV Switch for TR-MI65B in Place

MiniBooNE

Collider Detector at Fermilab (CDF)

- Flammable gas is off.

- The collision hall and detector survey has been completed

- Cable tray installed

- Power Outage on Saturday, March 18

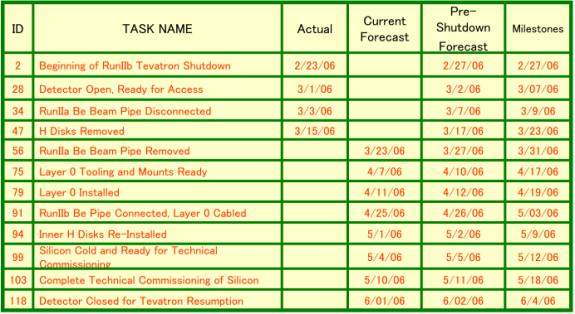

D-Zero (D0)

Layer 0

- Extraction of inner H disks completed

- Adapter card installation and testing completed

- Preparing to extract Run IIa beam pipe

- Trial run of transporting dummy Layer 0 to collision hall

Level 1 Calorimeter Trigger

- Installation of infrastructure in Movable Counting House nearly complete

Level 1 Central Track Trigger

- DFEA crates extracted and DFEA2 crates installed

AFE II

- Successful test of pre-production boards on platform

Detector Maintenance

- Southeast ICD drawer extracted for testing

Mechanical

Work is going well.

Cryogenics

Cryo Operations

- Tevatron at LN2 temperature and stable with magnet cryostat vacuum problems addressed well by MSD/Vacuum Group; B4 vacuum CIA controls crate work affecting B4 upstream magnet cryostat vacuum. No cryo problems with scheduled power outages of individual houses and feeders, though C-sector controls FE problems after C0 power outage allowed power leads to get too cold thus may have some frozen LCW lines (need checking for leaks once LCW pressures are restored). Helium losses are stable at 10 kscf/day (1/3-1/2 of normal during TeV operations). LN2 usage is stable and vendor deliveries are fine.

- F4, A3 and A1 are at room temperature and isolated with LOTO; E2 is slowly warming up to room temperature though magnet cryostat vacuum is still intact.

- ACNET application programs relating to FRIG operations are being tested on Linux consoles.

- MCR monitoring cryo operations.

CHL Maintenance

- General facility maintenance is in progress

- CHL Helium Compr “A” cooling tower installation is continuing with anticipated completion by month end.

- NRL maintenance is in progress, which includes overhauling the IR Booster Compressor (one piston rod needs repair) and cleaning the Niagara Intercooler for the TSI Compressor. Niagara Intercooler (see picture) had 6,000 pounds of mud/scale building) that is being mechanically cleaned; one Intercooler bundle was found with leak (corrosion) that will require repair. Marley cooling tower inspection/maintenance was completed by subcontractor. Estimate return of plant back to service is 2 weeks.

- Helium Coldbox-2 controls upgrade is in progress.

FRIG Maintenance

- Ring-wide overhauls of wet expanders in progress with 11/24 completed.

- Cryogenic Transfer Line E4-F1 air-to-vacuum leak at F1-end bellows was verified and repairs are in progress.

- Five IHI cold compressors were removed for inspection and are being overhauled.

- Various FRIG bldg vacuum maintenance and instrumentation repairs (e.g. lost charge on VPTs) are in progress, as well as support work on houses at room temperature and other equipment as things fail even during the shutdown period.

- Order has been placed for the new Kautzky relief poppets. Design change was made to help expedite the order. As soon as 250 are ready we'll send someone in to pick them up. This is enough to do one sector. Six houses (A1, A3, D4, E1, E2, and F4) were checked in place with only one suspected failure (D46-5) in addition to confirmed failure at F47-2.

- Controls Dept completed replacement of all FRIG Front End UPS units with new ones.

Various Mycom compressor maintenance is in progress: leak hunting and general repairs, F0#1 compressor replacement, F0#3 motor starter replacement

Cooling Tower Repair

Facility Engineering Services

95 Booster LCW system

CUB

- Shutdown went well

- Inspected the main tower water tank – minimal silt and shells

- Chiller #2 ran well (it was overhauled two weeks ago)

High Voltage

- Tunnel lighting completed in MI and Pbar

Site

- Hydrant flushing yielded ~500 lbs zebra muscle shells.

Instrumentation

Work continues.

RF

Work continues.

Controls

A CAMAC crate power supply will be replaced in the MCR on Tuesday, March 21

ES&H Upgrades

Data Acquisition System 95% Complete

- 16 of 17 Linux Ethernet Port Replicator (LEPR) chassis installed

- VME Data Acquisition Computer has been retired (Really Good Thing)

Booster 40% Complete

- Remove RDF Area

- Booster Dump Move Configuration Changes

Main Injector 15% Complete

- Lower Level Controlled Access Displays Replaced

- Main Injector Coasting Beam System changes

- Lam10 Critical Device Interface Installation

P-Bar Source 40% Complete

- Radiation Monitor Card Replacement

- Safety System Power Supply Replacement

- Interlock New BSC700 Beam Stop

Tevatron 50% Complete

- Moving location of both Tevatron Coasting Beam Gate Valves

MT6 Section 1 & 2 5% Complete

- Complete Enclosure Interlock System Upgrade

Safety System Testing 0% Complete

- All areas need to be re-tested before startup.

Equipment

- Air Packs and Oxygen Monitors checked out from the MCR need to be returned daily.

- There are a limited number of personal oxygen monitors available.

- Bump Caps – Expect more to arrive today

EE Support

On Schedule

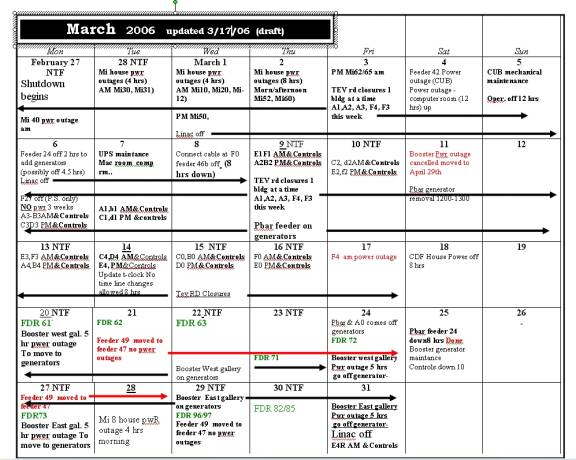

Shutdown Schedule for March 20 through to March 26

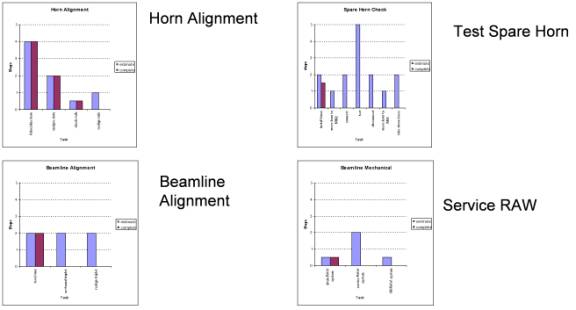

Alignment

- D-Zero 14%

- Meson Test 0%

- SwitchYard 120 60%

- Tevatron 25%

- MI-8 7%

- Main Injector 57%

- NuMI 15%

- Recycler 0%

- MiniBooNE 36%

- CDF 100%

- Booster 0%

- Pbar 26%

- Meson Center 30%

- 400 MeV 21%

Tevatron

- Completed “as founds’ for Pbar kicker and TEL #1

- Started D0 level run

MI

- Completed “as founds” for 608 and 402

NuMI

- Completed “vertical drops” for SR1

- Completed “as founds” for MI and NuMI

- Completed level run between MI-60 and NuMI SR3

MiniBooNE

- Completed level runs

- Fiducialized MiniBooNE Horn

CDF

- Completed the survey of the west side IMU steel

- Completed “as founds” for detector vertical checks and control

Add Ons

- Completed “as founds” for failed TeV dipole at F47-2

- Completed “as founds” for failed spool at F47-1

- 30% finished of magnet unrolls

Pbar

- Completed reference level run

400 MeV

- Completed 400 MeV stake survey on floor

- Completed 400 MeV Line Girder stake survey

Recycler

- Completed realign of 180 degree magnet

MIPP/E907

- 60% finished post-run “as founds”

Accelerator Update Archive

More Information

For Tevatron luminosity charts and the current status of Fermilab's accelerators and detectors (live!), please go to Fermilab Now.

Comments and Suggestions

What do you think about the Accelerator Updates? Please send comments and suggestions to: accelupdates@fnal.gov.

|