|

|

Méthode Champenoise:

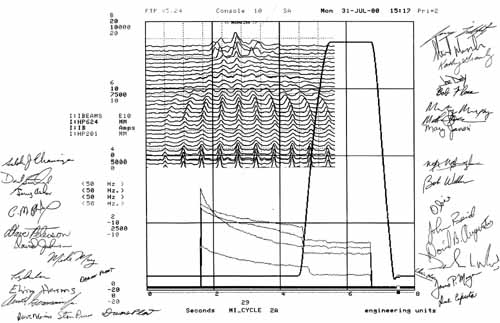

by Mike Perricone Carbonic acid (H2CO3), formed by combining carbon dioxide and water, is a mundane substance with a magical effect: during the final stages of fermentation inside a corked bottle, it turns wine into champagne, the sparkling stuff of celebrations. Fermilab's Antiproton Source Department broke out the bubbly on August 1 after effecting a little magic of its own: bringing antiprotons ("pbars") into the new Main Injector for the first time, accelerating them to machine's limit of 150 GeV, and coalescing several particle bunches into unit form fit for forwarding on to the Tevatron, all critical stages in preparing for Collider Run II in March 2001. "There's a lot of work yet to do, but we're well on our way to having the antiproton segment of Collider Run II ready to go," said Elvin Harms, deputy head the Antiproton Source. "There's another big step yet in getting them [antiprotons] injected into the Tevatron, but we proved we can do it in the Main Injector." The Tevatron, meanwhile, is prospering in its own preparations, reaching a record energy of 980 GeV for protons just days after the Antiproton Source success. But as anyone in the Antiproton Source will readily attest, protons are plentiful. Producing increased numbers of collisions in Run II pivots on providing an equivalent plenitude of antiprotons at equally high energies. Since it takes about a million proton hits on a fixed target to produce just 18-20 antiprotons, sending a million or more pbars around the two-mile Main Injector for the first time means coming by the champagne the old-fashioned wayˇearning it. Coalescing the antiprotons into a Tevatron-ready beam was an absolute must in achieving the champagne milestone. Coalescing sounds simple enough: take several pulses (usually 11) of antiprotons at fairly uniform energy, spread out over time, and mold them into a single pulse, where the energy of the particles is spread out but the delivery is, in effect, all at once. It comes down to swapping energy for timeˇand it has demanded plenty of both.

Even the transfer from the Accumulator in the Antiproton Source is a serious undertaking: the beam travels about a half-mile of transfer beam before reaching the Main Injector. Protons (remember, they're far more plentiful than pbars) are used to make sure the transfer line is "tuned" to promote the highest efficiency and thus, the lowest beam loss. Protons (positive charge) are sent backward through the line, injected where antiprotons (negative charge) would emerge, and emerging where antiprotons would be injected. "If we have good results with protons," Harms explained, "then we have a high level of confidence that the efficiency will be just as good when we send antiprotons through." Efficiency is essential because the antiprotons undergo preparations for the Main Injector similar to preparations for the Tevatron. The energy distribution in the antiproton beam is Gaussian (classic "hump," or bell curve), but the Main Injector requires more uniformity in the nine pulses inserted with each transfer. The previous procedure involved using RF to pull beam out of the top of the hump; now, that hump will be (metaphorically) shaken back and forth for about five minutes to produce a rectangular shape. Then RF will be used like a cleaver for what's called "unstacking," slicing off nine uniform segments to send on to the Main Injector. Four "clumps" of nine slices each are sent into the Main Injector, where the RF shaking and cleavering are repeated to produce the all-important coalescing, forming four "superclumps." Filling the Tevatron requires coalescing nine superclumps. Even as it's being developed and perfected, the new coalescing process is being automated. A new "sequencer" is being programmed for computer control of the RF frequencies and the durations of shaking the beam into its rectangular shape and paring off the slices. "In the big picture, we hope it will mean faster transfers with greater efficiency, achieving maximum luminosity and making the collider operation more routine," Harms said. "The sequencer will take the old 15-page, densely-printed checklist we had in the early days, and make sure every step is followed. It reduces the chances for human error. We're not quite at the stage of just pushing a button and making it happen, but we're close." Even then, there will still be room for magic, especially the carbonic acid kind.

|

| last modified 8/25/2000 email Fermilab |

FRLsDFx9eyfrPXgV

"We've been working seriously on this since January, and in some sense the entire Beams Division has played a role," Harms said. "We've been coordinating efforts between the Antiproton Source, Controls, Main Injector and RF [Radiofrequency] and Instrumentation Departments. We meet every morning at 9:30, and talk about the focus of the day's studies. We've been typically spending three days a week just making pbars and sending them on."

"We've been working seriously on this since January, and in some sense the entire Beams Division has played a role," Harms said. "We've been coordinating efforts between the Antiproton Source, Controls, Main Injector and RF [Radiofrequency] and Instrumentation Departments. We meet every morning at 9:30, and talk about the focus of the day's studies. We've been typically spending three days a week just making pbars and sending them on."