Low-mass, low-power photon detectors in testing

|

|

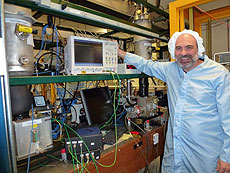

Paul Rubinov stands in front of PPD testing equipment formerly used with the Dark Energy Camera.

|

In a dimly lit room within Fermilab's SiDet building, scientists are testing the next generation of extremely light-sensitive detectors. Known as pixelated photon detectors (PPD), these tiny silicon chips play an instrumental role in the particle physics detectors of the future.

They are the key to the continuing evolution of medical imaging devices like PET scanners.

About five years ago, the development of PPDs was a major breakthrough. Compared to the traditional photomultiplier light detectors that are based on a vacuum tube concept, the silicon chips are cheaper, lighter, more compact and more robust. PPDs are also insensitive to magnetic fields and require much lower voltage. All of these advances mean PPDs are an entirely different technology from photomultipliers.

But PPDs are a very new and not completely understood technology. The chips undergo rigorous testing, as their successful performance could mean a lot to future particle physics experiments and to private industries worldwide. The testing has to be done very carefully, with every aspect of the room taken into account.

"I think they make the room look quite nice," commented Fermilab physicist Adam Para about a pair of floor lamps he flipped on as he stepped into the room in his clean suit.

The overhead fluorescent lights would create too much background interference with the sensitive tests. Even the lasers delivering photon bursts have to first send a light signal through long coils of fiber optic cables in order to eliminate noise.

"Sensitivity to the details of the operating conditions is the main challenge," Para said.

Within a steel cube, a silicon chip a quarter the size of a computer key is mounted on a block of copper. It's a conductive metal that's easily cooled by the liquid nitrogen pumped into the cube or warmed by an inch-long heater attached to the block. Starting at minus 175 C and running up to 60 C, each chip is gradually warmed. Responses to individual photons are recorded and carefully analyzed to tease out details on how well the PPD is functioning.

The greatest challenge for PPDs is a temperature-induced jittering effect called a thermal excitation, which creates spontaneous signals indistinguishable from those of the photons. For each type of detector, the testing will determine the threshold for excitations, measuring how the device responds at different temperatures and voltages.

"Because they're completely new, there's no easy way to read them," Para said, gesturing to a series of electronic boards that send out a specific voltage to each chip while measuring the photon readings. "So that's why our engineers built these electronics."

In a storage cabinet in another part of SiDet, an array of PPD samples sent from vendors await testing. One case Para pulled out contained four chips secured within cufflink-sized cases shipped from a company in India.

"I am doing these tests so I can give vendors a precise recipe that will provide valuable advice and feedback for the chips," Para said.

In Para's ongoing tests, innovations in testing technology and creative reuse of laboratory equipment are providing a better understanding of the new PPDs. As a result, the new technology will play an instrumental role in the calorimeters and muon detection systems of particle physics experiments in the future.

—Brad Hooker

|