Fermilab, Japanese team earns superconductor technology award

Fermilab and Japanese collaborators have expanded the practicality of a cutting-edge superconductor for use in accelerator magnets, creating a path to new uses of high-field magnets in particle physics, medicine and nuclear fusion. For this achievement, Fermilab's Emanuela Barzi and Ryuji Yamada are sharing with Japanese colleagues the prestigious Japanese Superconductor Science and Technology Award.

The scientists optimized niobium aluminum, Nb3Al, through a fabrication process called Rapid Heating Quenching and Transformation, or RHQT, and copper plating. This enables scientists to form niobium aluminum into long wires and cables that can withstand high-magnetic fields, above 15 Tesla without losing its superconductivity. The creation of the world's first fully copper-stabilized Nb3Al wire longer than one kilometer allows access to commercial applications and higher-energy accelerators. The material also provides a potential option, in addition to niobium tin, for planned upgrades to the LHC accelerator.

This leap in superconductivity technology earned those researchers one of the top Japanese awards for superconductivity research, the Superconductor Science and Technology Award. The award citation praised the researchers for widening the applications of Nb3Al wire.

On April 13 the Japanese Society of Non-Traditional Technology gave the award to Yamada and Barzi from Fermilab and their Japanese colleagues Akihiro Kikuchi and Takao Takeuchi from the National Institute for Materials Science, or NIMS; Kiyosumi Tsuchiya from KEK; Kazuhiko Nakagawa from Hitachi Cable Ltd.; and Michio Kobayashi from Hikifune Co. Ltd. This award, recognized by the Science and Technology Agency of the Prime Minister's Office, has been given to only one other non-Japanese recipient in its 14-year history.

"This prize is not only a welcome recognition for the collaborative effort between Japan and U.S. laboratories, but shows our capability to strive and make serious technical advances on one of our core competencies: the R&D on superconducting magnets," said Giorgio Appollinari, head of Fermilab's Technical Division. "The effort to develop new technologies - in this case new superconducting cables - is essential to maintaining Fermilab's preparedness for future applications and the development of basic technology for superconducting magnets."

he ability to withstand high-magnetic fields without degrading the performance of the superconducting wirecould allow researchers in a multitude of fields to upgrade existing technology such as MRI machines and potential future high-energy particle colliders such as a muon collider.

High-magnetic fields are used in accelerators. As the accelerator beam's energy increases, the magnetic field needed to bend and focus the particle beams also must increase.

Currently, in accelerators, the commonly used niobium titanium magnets function up to 10 Tesla. Under development for accelerator use is niobium tin, which functions with some degradation up to 16 Tesla. R&D on high-temperature superconducting, or HTS, magnets point to superconductivity that starts at a minimum of 20 Tesla. R&D is being conducted to try and expand the ranges of both types of magnets, but, in the meantime, some researchers think magnets made with Nb3Al cables could have the potential to fill the void between the two.

Prototype tests show Nb3Al can withstand more pressure than niobium tin to the forces of magnetic fields, but can't yet match the amount of electrical current niobium tin can carry. Fermilab and Japanese researchers hope to close the gap with further R&D.

The path to the award began in 2005 when Kikuchi at NIMS developed a way to add a copper electroplating to the RHQT Nb3Al wire, which was previously developed at NIMS. That stabilized it so that it did not lose superconductivity from disturbances such as overheating. This milestone opened the door to uses at higher-magnetic fields.

Kikuchi collaborated with a team of about a half a dozen people at Fermilab who tested many Nb3Al wires and to increase the wire's stability. They also improved on the material inside the wire surrounding the Nb3Al filaments and worked successfully to bundle wires into Rutherford cables, essential for creating coils inside accelerator magnets. They also created and tested prototype racetrack-style coils, proving the viability of Nb3Al wire as a conductor for high-field magnets, according to the award citation.

"This achievement shows how productive collaborations born out of a genuine push for advancement in science and technology can be, and how critical it can be sometimes in science to pursue visions that are out of the mainstream," Barzi said.

-- Tona Kunz

|

|

| From left: Allen Rusy, who is in charge of cabling, and Dan Turrioni, who is responsible for cable tests, inspect the cabling machine used to make the Nb3Al cable. |

|

| Igor Novitski and Jesus Alvarez (from left) from Fermilab's superconducting magnet group work with a Nb3A1 prototype design. Marty Whitson, far right, contributed to the project. |

|

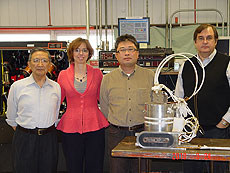

| From left, scientists Ryuji Yamada, Emanuela Barzi, Akihiro Kikuchi and Alexander Zlobin stand behind the small racetrack coil made of the new Nb3A1 conductor. |

|